FUEL GAS CONDITIONING

Aspen Engineering Services offers a Fuel Gas Conditioning (FGC) process to condition rich natural gas for use in natural gas engines. The dual stream cooling process lowers the gross heating value of the gas to 1150 BTU/SCF regardless of the BTU content of the feed gas at a lower pressure than the Joule Thomson process.

The patented FGC process eliminates the need for de-rating natural gas engines, commonly done to prevent engine knock caused by rich fuel gas. The engine will have a higher capacity and operate with less maintenance using conditioned FGC fuel gas.

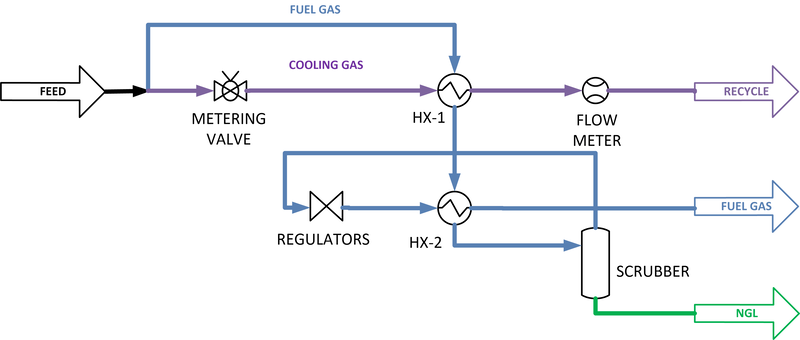

Rich feed gas is split into a fuel gas stream and the other and a cooling gas stream. A metered quantity of cooling gas flows through a depressurization valve before entering the cold side of a shell and tube heat exchanger HX-1. The cooling gas is discharged to a flare or recycled to the compressor. Fuel gas from HX-1 then flows through the shell side of the second shell and tube heat exchanger, HX-2. The cooled fuel gas is separated from condensed liquids in a fuel gas scrubber. The BTU of the fuel gas is adjustable by varying the cooling gas/fuel gas ratio.

Rich feed gas is split into a fuel gas stream and the other and a cooling gas stream. A metered quantity of cooling gas flows through a depressurization valve before entering the cold side of a shell and tube heat exchanger HX-1. The cooling gas is discharged to a flare or recycled to the compressor. Fuel gas from HX-1 then flows through the shell side of the second shell and tube heat exchanger, HX-2. The cooled fuel gas is separated from condensed liquids in a fuel gas scrubber. The BTU of the fuel gas is adjustable by varying the cooling gas/fuel gas ratio.